plating thickness tester for screws|examples of plating thickness : private label One common method is to use a thickness gauge, which can be a handheld device used post-plating or an inline measurement system integrated into the plating line for real-time monitoring. Inline systems are particularly beneficial for continuous processes as they allow for real-time adjustments to ensure the consistency of the plating layer.

Published 21.02.2019. Played 85.798. Enter a world of enchanting puzzles and cosmic wonder with "Hoshi Saga." This captivating online game, .

{plog:ftitle_list}

14 de dez. de 2023 · A décima terceira edição do Show de Prêmios do Grupo Shibata teve início no dia 1º de novembro. Este ano, a rede premiará 660 clientes, com prêmios que, somados, ultrapassam a marca de R$ 1 milhão. A campanha tem como objetivo comemorar o aniversário da Rede Shibata, que neste ano completa 47 anos de existência e vai de .

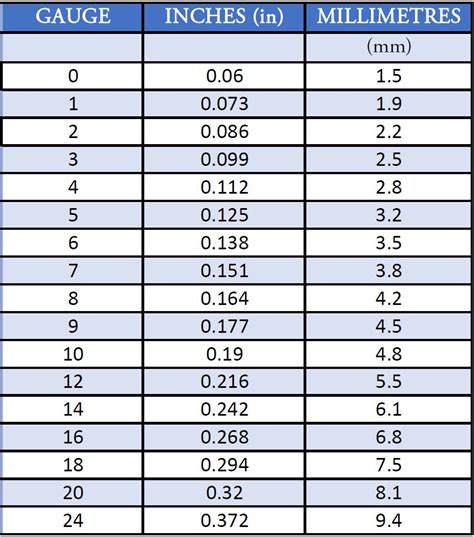

To determine pre plating dimensions for thread ring gages: For thread ring gages subtract the max plating thickness from the P.D. of the Go thread ring gage. Then subtract the minimum plating from the P.D. of the No Go thread ring gage.In the major and minor diameters, the calculation does not depend on the head angle, and the difference is always twice the coating thickness. In 60° threads (e.g., Metric, Unified inch, . Non-Destructive Testing: These gauges typically employ non-destructive testing methods, which means they can measure the plating thickness without damaging the underlying material. Versatility: They can be .The LS225+F500 plating thickness gauge is widely used in metal processing industry, hardware and other industries and is particularly suitable for testing small-sized materials with a minimum measurement area diameter of only 7 .

High quality Linshang LS225+F500 Paint Gauge Plating Thickness Tester For Screws Bolts Plating Coating Thickness Plating Plated LS225+F500 from China, China's leading Leather Thickness Gauge product market, With strict .One common method is to use a thickness gauge, which can be a handheld device used post-plating or an inline measurement system integrated into the plating line for real-time monitoring. Inline systems are particularly beneficial for continuous processes as they allow for real-time adjustments to ensure the consistency of the plating layer.

Q: What should a coating thickness gauge read on a G90 galvanized coating? A: According to ASTM A653, a G90 coating designation means the weight of zinc on both sides of a steel sheet is 0.90 oz./ft2. A magnetic thickness gauge measures only one side. Therefore: 0.45 oz./ft2 x 1.684 = 0.76 mils per side; 0.45 oz./ft2 x 42.78 = 19 microns per side

The corrosion system of a screw assembly should, under operating conditions, be at least as corrosion-resistant as . Depending on the layer thickness 500 h or 1000 h in fog test (DIN 50021). Burnishing (blackening) Chemical procedure. . Two coating metals No layer thickness prescribed – 0 3 – 1 5 2+3 2 8 3+5 3 10 4+6 9 12 4+8 4 15 5+10 .We offer Digital Coating Thickness Gauges, which are designed on the conception of ultrasonic sound waves. Organized to offer highly accurate, dependable and repeatable coating thickness measures, these are perfect to be used on almost all substances, be they are ferrous or non-ferrous. . Coating quality testing, paint adhesion testing, color .The Kocour 6000 digital Thickness Tester utilizes the coulometric principle. A small test area is anodically deplated with an electrolytic solution applied at a constant current. Because the testing solution is selective, it removes only the plating. Thickness is determined by the current and time required to remove the plating.Coating Thickness Gauge คือ เครื่องมือใช้ตรวจวัดค่าความหนาของผิวเคลือบสีที่อยู่บนโลหะ (Ferrous) หรืออโลหะ (Non Ferrous) (ตามตัวอย่างรูปที่1)

Nails and other fasteners are coated to protect them against rust; the thickness of the zinc layer corresponds directly to how long they can resist corrosion.Thread Check provides detailed information about the importance of calculating pre plate screw threads and gages. Learn more. . If no minimum and maximum plating thickness is given , then the given plating thickness is considered nominal or minimum plus 50% to determine maximum plating. . Hardness Testing; Feeler Gauges; Production .The Elcometer 456 Coating Thickness Gauge is a handheld gauge for fast and accurate measurement of the thickness of coatings on metal substrates. The gauge is available in four models; Model E, B, S and T. . Screw in the collar - clockwise 1 1 2 2 + + www.elcometer.com 6 R Fitting the wrist harness en A wrist harness is supplied with each .The effect of plating on a 60° screw thread is a change in PD of 4 times the plating thickness (2 times on each side). That is because the plating itself is parallel to the thread flanks, and the PD is measured perpendicular to the thread axis. . One Value Plating Thickness. When the plating thickness requirement is given with a one value .

Film Thickness Meter. Taiwan Nakazawa represents well-known brands such as British Eloometer film thickness meter, German ERICHSEN, British Eloometer, and British Oxford instrument OXFORD: X-ray fluorescent film thickness measuring instrument series, 200 series coating (plating) layer thickness tester, hardware, screws, insulators and Electroplating .

Beli Digital Plating Thickness tester Gauge LS225 with F500 Probe for di Citra Teknologi Utama. Promo khusus pengguna baru di aplikasi Tokopedia! . Digital Plating Thickness tester Gauge LS225 with F500 Probe for Screws Bolts Coating Thickness below 10μm Test fixtures are not included. To purchase, please contact us!ASTM Specification B 633 lists four classes of zinc plating: Fe/Zn 5, Fe/Zn 8, Fe/Zn 12 and Fe/Zn 25. The number indicates the coating thickness in microns (µm). The coating finds application in screws and other light fasteners, light switch plates and other small parts.Environmental Conditions Wear/Abrasion Conditions Examples Suggested (Minimum) Thickness ISO 2081 Designation; Dry, clean, indoor: Minimal: Offices, domestic premises (excluding kitchens and bathrooms) Maintaining plating thickness as specified by a buyer and applicable standards is critical for the quality and longevity of the end product. In order to be sure that a component’s thickness is correct and consistent, tight controls must be maintained during the entire plating process. A key function to achieving this is accurate plating thickness.

Linshang LS225+F500 Plating Thickness Tester Paint Gauge for Screws Bolts Coating Thickness of Electroplated Plating Clad Layer. Related items. Customer Reviews Specifications Description Store You may also like Customer Reviews. Specifications. Brand Name. linshang. There are various methods of applying zinc coatings to fasteners and hardware items which are often marketed as equal to or better than hot-dip galvanized (HDG) fasteners. In reality, the longevity of all zinc coatings (regardless of application method) is directly related to coating thickness, and abrasion resistance is affected by a metallurgical vs. mechanical .SGS MSi can perform plating thickness testing using SEM and optical microscopy and testing to ASTM B748, B747, E3-11 and A90. Contact our lab to learn more. Skip to main content (708) 343-3444; . SGS MSi can perform plating thickness using SEM and Optical Microscopy (Image Analysis) on material as thin as .25 microns (.000010 in. or 10 micro .The Triplett Model CTT42 Coating Thickness Tester uses smart automatic recognition of ferrous (magnetic induction) and non-ferrous (eddy current measurement) substrates. Ideal for paint shops and electroplaters, chemical, automobile, shipbuilding, and aircraft industries. Use in the laboratory, workshop, or field. Read

The Buyer/User, through its own analysis and testing, is sole ly responsible for making the final selection of the products and for assuming that all performance, safety and warning requirements for the application are met. . Typical thickness of electroless plating can be as thin as .0005" and up to.010". Electroless coatings,This combined test will help you to do all 3 in the least amount of time. Drive Test. Drive Torque Test (Thread Rolling Screws only). Hydrogen Embrittlement Test. B. D. E. Place flat washers on 13 screws to insure tension underhead upon seating. Drive all screws into the specified test plate so that the major diameter Of the screw thread pro-

It fulfils a long standing need on the market for reliable, accurate & Economical Plating Thickness Tester for all type of Plating. There is no separate cost for each PBC Plug. Model -Ptt Eco. Specifications: Principle: Coulometric: Type: Destructive: Measuring Range: 00.1 to 99.9 microns: Resolution: 0.1micron:

Screw Joint for Tension and Compression; Compressive Force Dynamometers; . Our handheld devices Cpad X300 and X400 for coating thickness measurement work with ultrasound. This makes it easy to determine e.g. the thickness of paint layers or galvanised layers. . Coating Thickness Tester Cpad T400 502 KB. Hardness Tester Lpad H100-110-120 927 KB.

The American Society for Testing and Materials (ASTM) . SC3 or SC4) – to define the minimum plating thickness required according to the type of environment. Service Condition 1 is for mild or indoor applications whereas service condition 4 is for very severe or highly corrosive applications. ASTM B633 Chromate Specifications Type Chart .

Loop Tack Tester inc

pre plate screw gage chart

plating thickness pitfalls

Resultado da Kinechan Onlyfans. 4 818 subscribers. View Post. View context. If you have Telegram, you can view post and join .

plating thickness tester for screws|examples of plating thickness